If a company is producing t-shirts, the cost of the fabric would increase as the company produced more shirts, and decrease as they produced fewer shirts. This is an example of economies of scale, or the cost advantage companies get when production becomes efficient. And the more units sold at marginal cost, the higher its contribution to the net income.

How to Identify and Compare the Incremental Costs and Benefits of Different Alternatives?Original Blog

- The incremental cost is a key concept in business planning and budgeting decisions as it helps management to understand how much more money must be invested in production when demand increases.

- Understanding incremental costs is beneficial in making the right decisions, making profits, and preventing losses.

- Let us assume you are in the shirt manufacturing business and spend $100,000 to make 10,000 shirts.

- In other words, they are also the additional costs incurred to produce an additional unit of product in excess of the current output.

- Getting all relevant information about your operational expenses lets you know whether you are in the right financial state to cover additional production costs before starting any project.

Incremental cost is usually computed by manufacturing entities as a process in short-term decision-making. It is calculated to assist in sales promotion and incremental cost meaning product pricing decisions and deciding on alternative production methods. Incremental cost determines the change in costs if a manufacturer decides to expand production.

Incremental Cost vs Marginal Cost: 5 Ways They Affect Your Business

Incremental cost reflects the expense a company incurs to produce one additional unit of a product. By focusing on incremental costs, companies can assess and maximize the profitability of their business segments. Understanding this cost component assists in fine-tuning production strategies, improving efficiency, and informing important pricing and investment decisions. As businesses get an understanding of Incremental Costs, it would help them to improve the overall efficiency while saving money at the same time. Such cost also tend to be useful when it comes to deciding whether to manufacture a product or purchase the same from some other place. When you get an understanding of the additional costs of increasing the overall production of a product, it serves to be useful in the determination of the retail price of the particular product.

Simple Advertising Techniques to Increase Shopify Incremental Profit Margins

This concept is crucial for businesses when making decisions about scaling up production, launching a new product line, or changing a business process. A very simple example would be a factory making widgets where it takes one employee an hour to make a widget. As a simple figure, the incremental cost of a widget would be the wages for the employee for an hour plus the cost of the materials needed to produce a widget.

Difference Between Incremental and Marginal Cost

The use of the Incremental Cost-Effectiveness Ratio (ICER) in healthcare decision-making raises several ethical considerations, particularly concerning equity and access. At the heart of these concerns is the question of whether decisions based on ICER might prioritize cost-efficiency over the needs of individual patients, especially those belonging to vulnerable populations. By systematically comparing the costs and outcomes of different healthcare options, ICER helps to ensure that limited healthcare resources are used in a way that maximizes health benefits for the population. Central to the economic evaluations within HEOR is the Incremental Cost-Effectiveness Ratio (ICER), a crucial metric that compares the relative costs and outcomes of different healthcare interventions. ICER is defined as the difference in cost between two possible interventions, divided by the difference in their effectiveness. Due to economies of scale, it might cost less in producing two items than what was incurred in producing each one separately.

Incremental Cost vs. Incremental Revenue

To stay on top, compare every new expense with how much money it could bring in or save. Smart managers use increments to guide retained earnings them toward better returns on investments. Always weigh the small changes, for they can steer your business to grand successes.

What Is Incremental Manufacturing Cost and How Is It Calculated?

- They’re the backstage players that influence whether you turn a profit or face unwelcome surprises on your balance sheet.

- If the incremental cost of producing additional units is higher than the selling price, then it is not profitable to produce them.

- It is used to assess how viable a project is by considering how it will impact borrowing costs for a business.

- Incremental cost refers to the additional cost incurred by a company when producing an additional unit of a product or service.

- You have done some market research and believe that there is demand for your product in the new location.

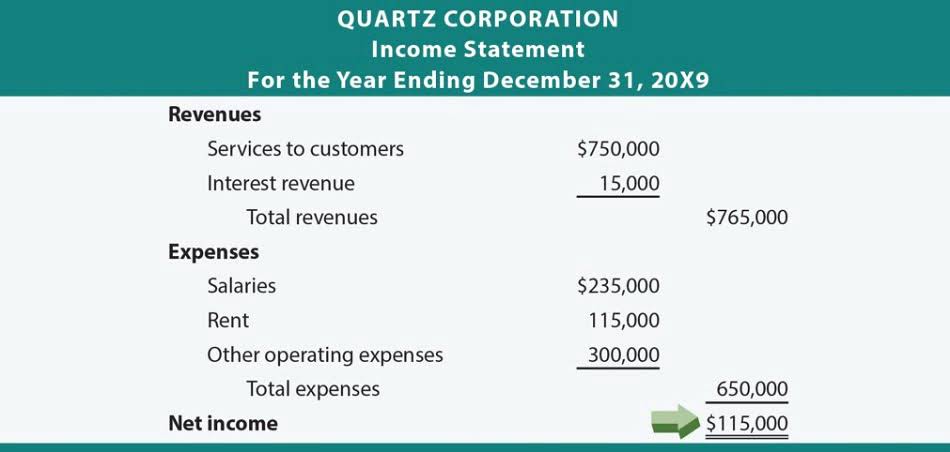

The incremental cost was kept lower at $70,000 while producing twice its production capacity, leading to a higher net income. Here are some incremental cost examples based on different scales of production. https://www.bookstime.com/ The first step in calculating the incremental cost is determining how many units you want to add to your normal production capacity. Therefore, the incremental cost of producing an extra 5,000 units is $20,000. Add up all the production and direct labor costs involved with your base volume. Include material, labor, transportation, etc. required to sustain the base case output.

- Learn about the definition and calculation of incremental costs in finance, along with examples, to better understand their significance in financial analysis.

- ICER is defined as the difference in cost between two possible interventions, divided by the difference in their effectiveness.

- The cost of producing 15,000 units is $120,000, meaning the additional cost to expand your production to this level is at an incremental cost of $20,000.

- From this example, you can observe not all increase in production capacity leads to a higher net income.

- To stay on top, compare every new expense with how much money it could bring in or save.

- If you use Excel, create a dedicated spreadsheet for production tracking with formulas to calculate changes automatically.

- Once a flight is scheduled, many costs become fixed—the aircraft lease, airport fees, minimum crew requirements, and scheduled maintenance.

Expanding from 10,000 units to 15,000 units, let’s assume total monthly costs increase to $120,000. This means the cost of production to make one shirt is at $10 in your normal production capacity. Incremental costs are also referred to as marginal costs, but there are some basic differences between them.